The Wire Mesh Applications in the Automotive Industry

Wire mesh, with its excellent ventilation and heat dissipation properties, high strength and rigidity, as well as breathability, transparency, and aesthetic appeal, has become an indispensable material in the automotive industry. Below are the common wire mesh applications in automotive industry:

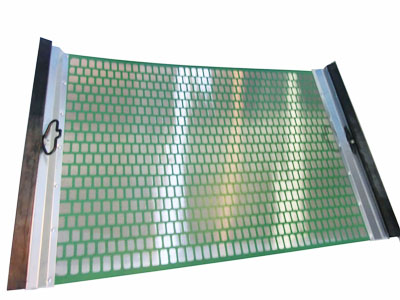

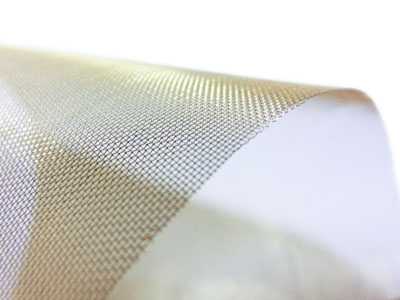

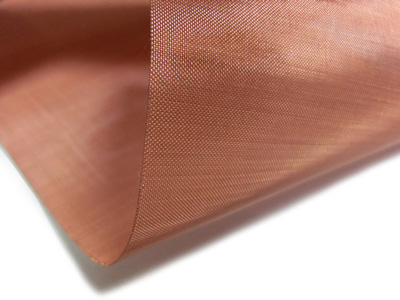

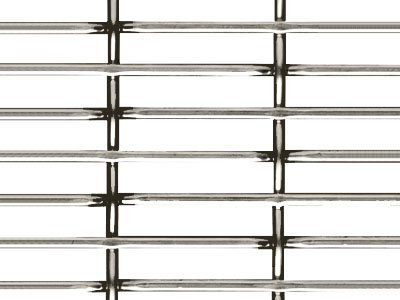

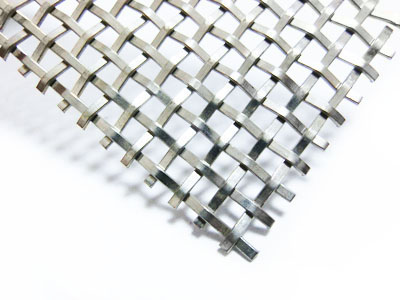

Wire Mesh for Car Grilles

Wire mesh is widely used in car front grilles. It acts as a protective barrier, preventing debris and larger particles from entering the engine compartment while maintaining proper airflow for cooling. Additionally, Wire mesh is also used in ventilation systems to ensure adequate air circulation in areas such as air intakes and interior vents.

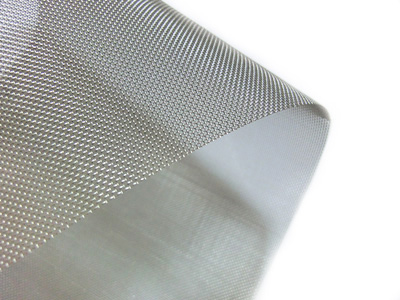

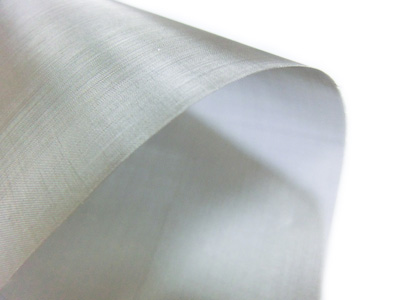

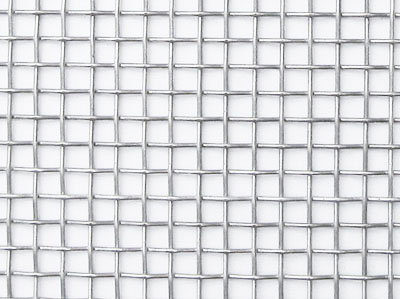

Wire Mesh for Air Filtration

Wire mesh is an integral part of a car's air filtration system. It is used as the support structure of the air filter, which can effectively filter dust, pollen and other particles in the air, keeping the air in the car fresh and healthy.

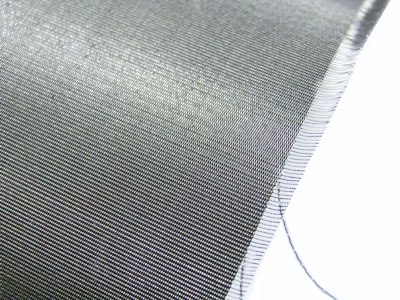

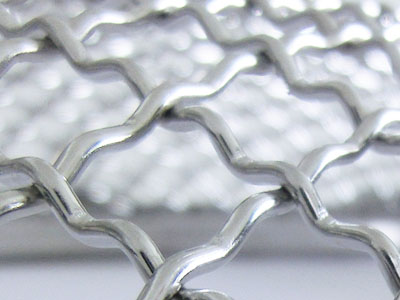

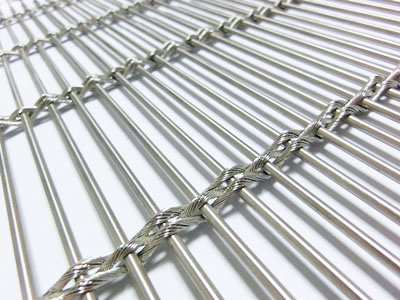

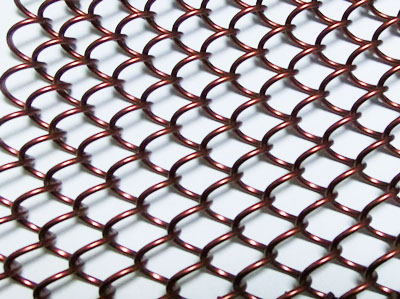

Metal Mesh for Automotive Speakers

Metal mesh, commonly referred to as speaker grills, is an essential component of car audio systems. The use of metal mesh in speakers prevents dust and debris from entering the magnetic gap of the diaphragm, which could cause sound distortion, while also enhancing high-frequency performance.

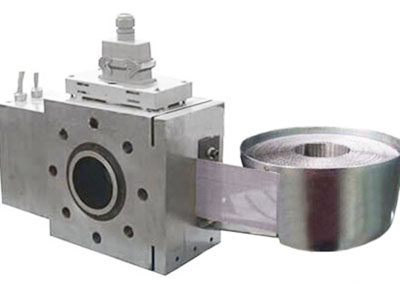

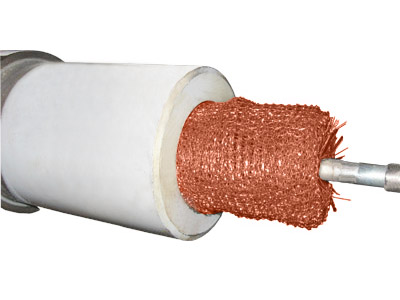

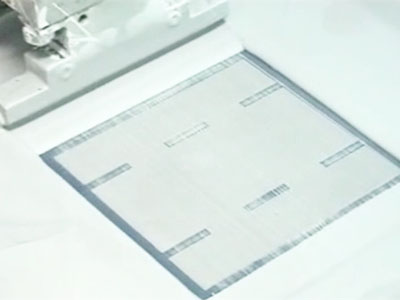

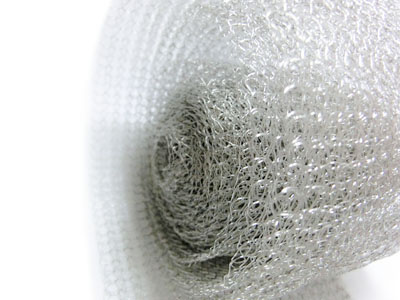

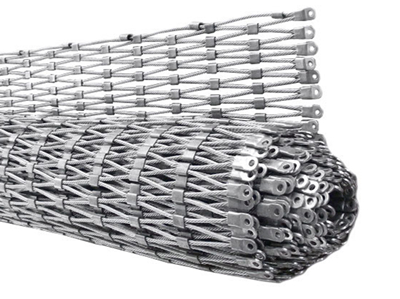

Wire Mesh for Safety Applications

Wire mesh plays a crucial role in automotive safety applications. In safety airbags, which are one of the most commonly used safety devices, wire mesh is an essential component of the airbag inflator. It ensures controlled air release during accidents, effectively protecting passengers.

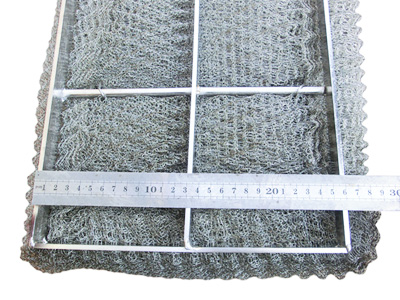

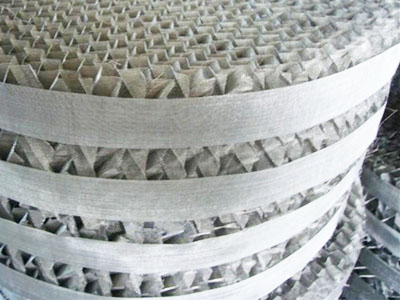

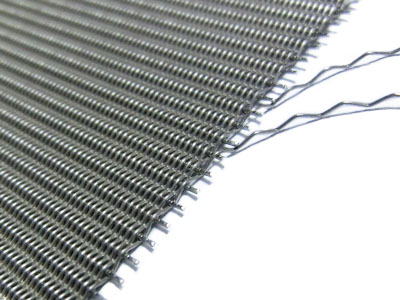

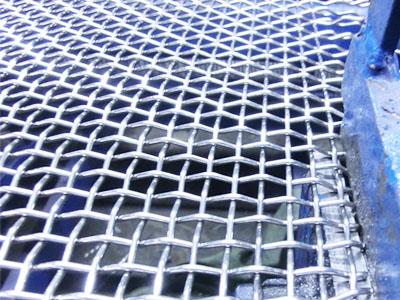

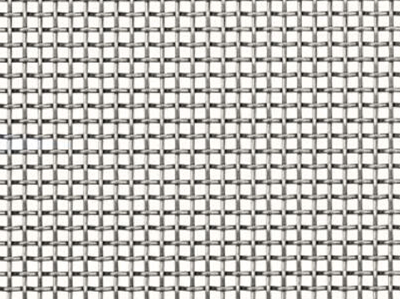

Wire Mesh for Automotive Mufflers

Wire mesh is also vital in car mufflers, which are designed to reduce the noise generated by engine operation. The anti-explosion mesh in automotive mufflers is positioned within the exhaust system to dampen vibrations, reduce noise, and filter exhaust gases. It plays a critical role in ensuring driving safety while reducing noise and pollutant emissions.