Development Direction of Metal Wire Mesh Industry

Driven by rapid global economic growth and technological advancements, the metal wire mesh industry is experiencing unprecedented opportunities and challenges. In order to maintain their advantages in the fierce market competition, metal wire mesh enterprises must keep up with the latest trends, actively adjust their development strategies, and meet the five key trends of future development

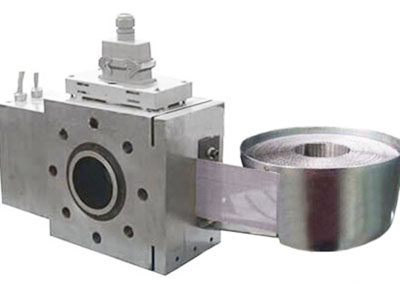

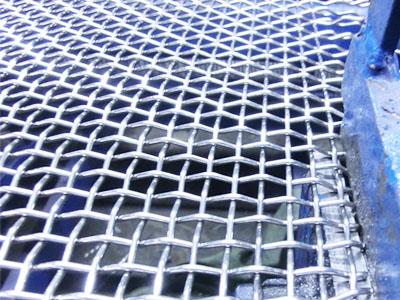

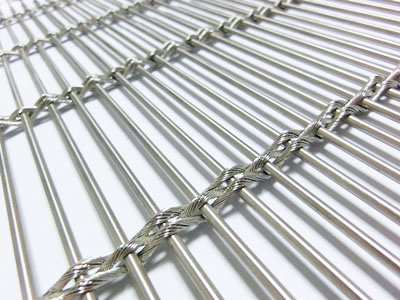

1. Intelligent and Automated Production

Intelligent and automated production is an undeniable trend in the metal wire mesh industry. As labor costs rise, traditional manufacturing methods must shift toward greater intelligence and automation. By introducing advanced production equipment and robotics, production efficiency can be significantly improved. This approach also minimizes the impact of manual operations on product quality, ensuring higher quality and more stable production processes.

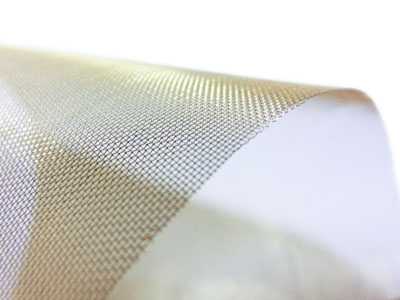

2. Environmental Protection and Energy Conservation

With the growing global awareness of environmental protection, the metal wire mesh industry faces increasing demands for eco-friendly and energy-efficient practices. Manufacturers should focus on reducing pollutant emissions and energy consumption during production. Through technological innovation and equipment upgrades, cleaner production methods can be achieved. Additionally, the design and material selection of products should prioritize environmentally friendly and energy-efficient materials to minimize environmental impact.

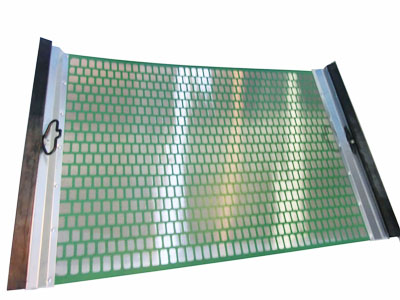

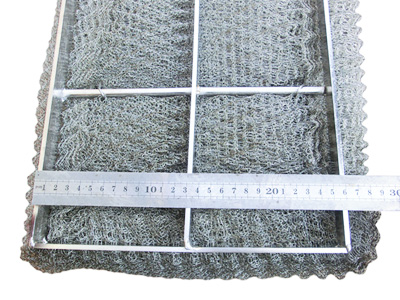

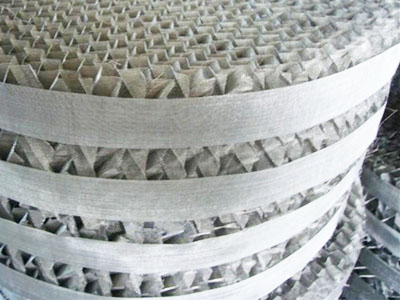

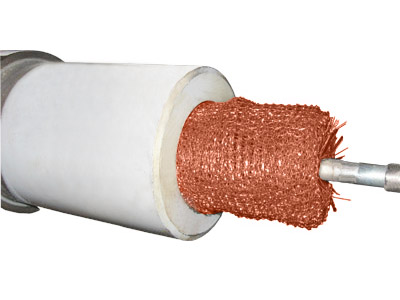

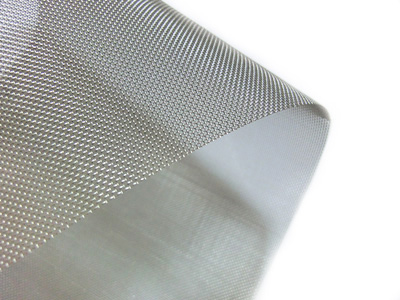

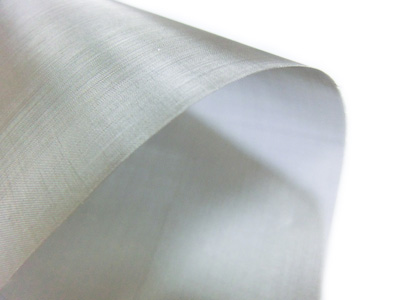

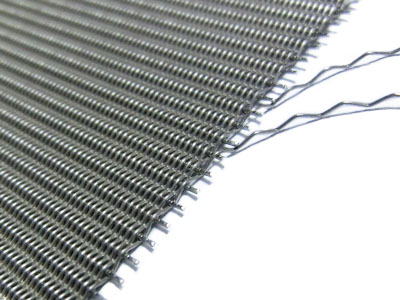

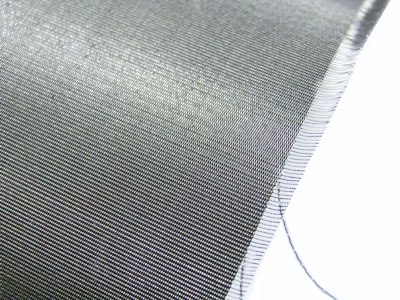

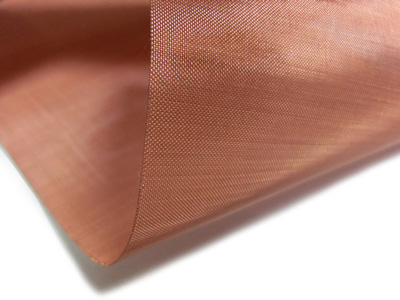

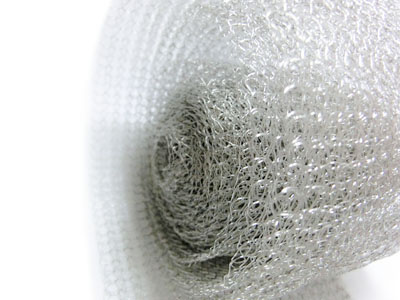

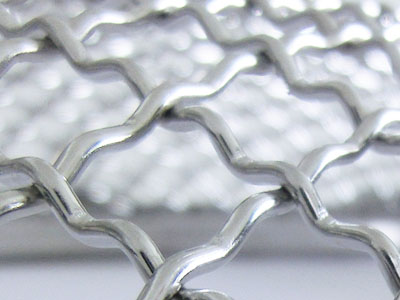

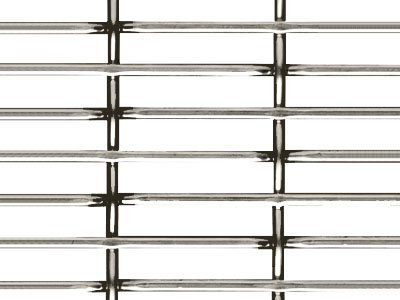

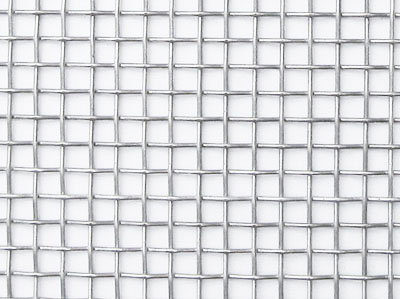

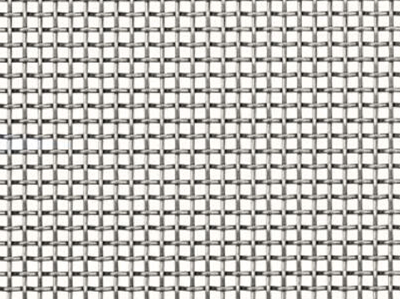

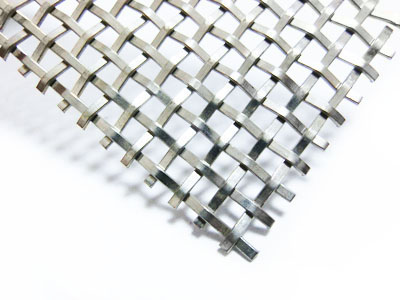

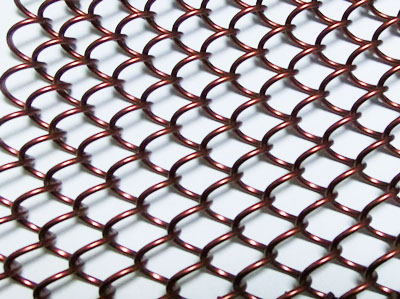

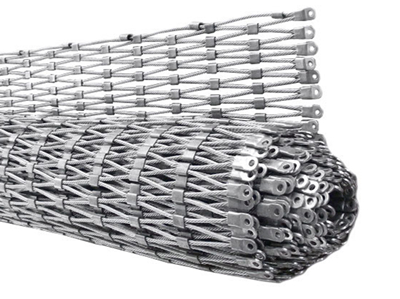

3. Precision and High-End Development

The future development of the metal wire mesh industry will place greater emphasis on precision and high-end products. As technology advances and market demands evolve, the applications of metal wire mesh are expanding beyond traditional industrial materials. While exploring new application fields, enterprises should also focus on product upgrades and innovative designs to enhance product value and quality, meeting diverse market needs.

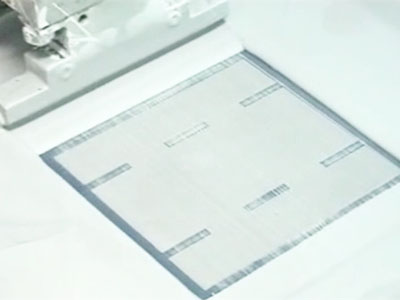

4. Digitalization and Informatization

Digitalization and informatization are essential components of national industrial upgrades and represent a significant trend for the metal wire mesh industry. By establishing digital and information-based systems, companies can achieve automation, intelligence, and precision in both production and management, thereby improving efficiency and quality. Additionally, digitalization and informatization enable enterprises to conduct more accurate market positioning and analysis, further enhancing their competitiveness.

5. International Cooperation and Exchange

As a globally integrated industry, metal wire mesh has widespread applications worldwide. Wire mesh companies need to engage in close cooperation and exchanges with domestic and international peers to gain insights into market demands and technological trends. Learning from experiences and innovations can enhance your core competitiveness. Actively participating in international exhibitions and conferences is also crucial for expanding global markets and forging cooperative opportunities, paving the way for international development.