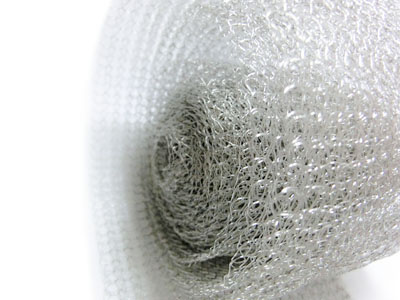

Knitted Wire Mesh Forms

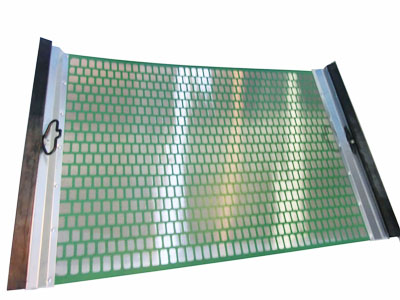

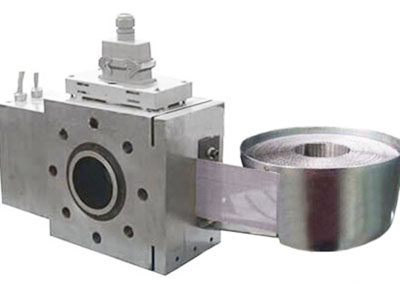

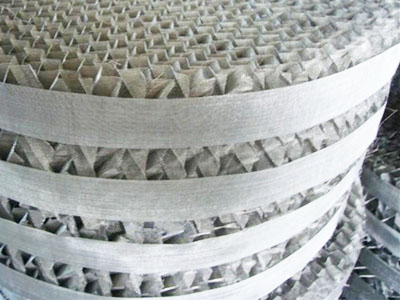

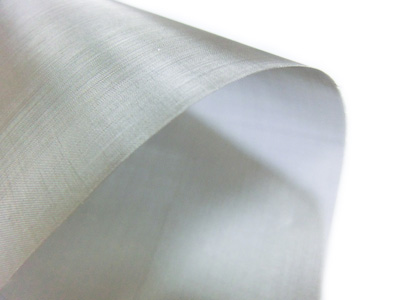

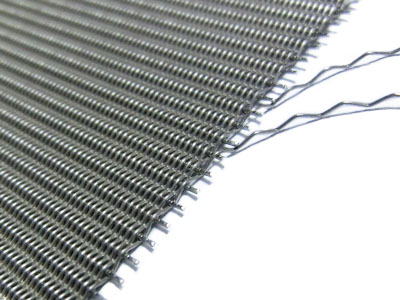

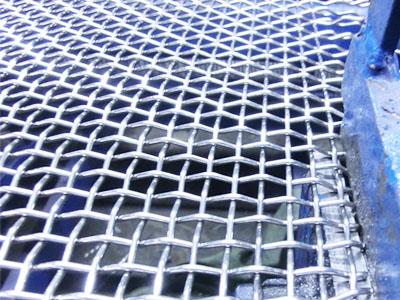

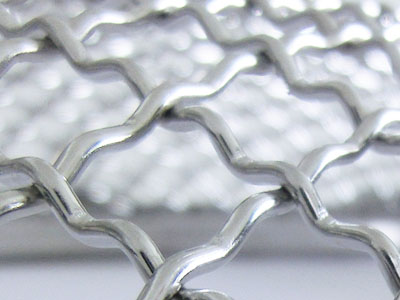

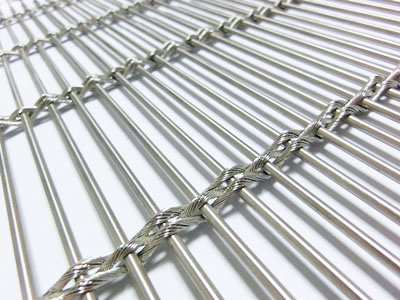

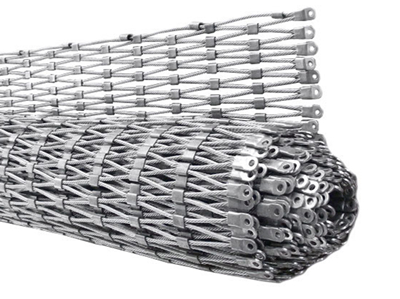

Crimped Knitted Wire Mesh is a processed knitted wire mesh product used to create compressed units for filtration, shock mounts and flame arrestors. The mesh can be formed via two methods:

1. Pulling through a custom made die to compress the material.

2. Running the mesh through calendaring rollers to create a continuous strip of compressed mesh. The finished product is available in densities (% metal by volume) ranging from 10% to 70%, depending on the performance needs of your application.

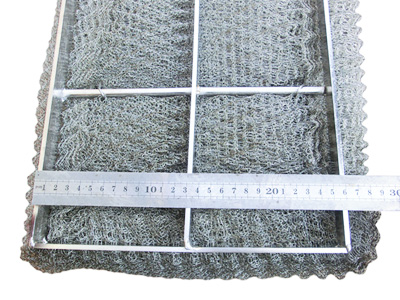

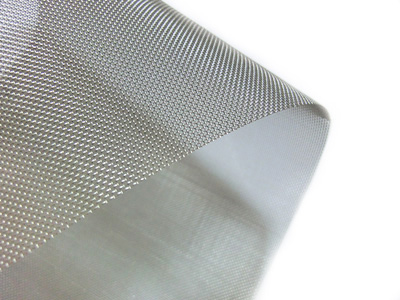

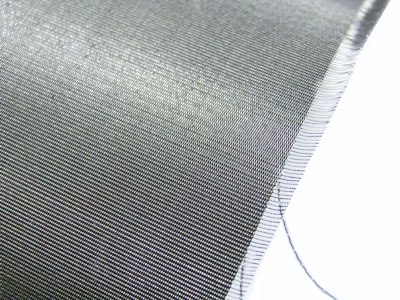

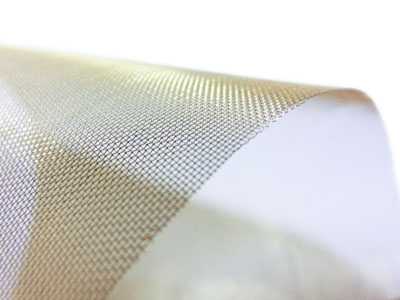

Shaped Knitted Wire Mesh uses the natural resiliency of the material to maintain a desired shape in your application. Because each loop acts as a small spring when subjected to tensile or compressive stress, knitted metal has an inherent resiliency. If it’s not distorted beyond its yield point, the material will resume its original shape when the stress is removed. Even when it’s compressed into a special shape, a high degree of resiliency is retained. Varying the knitted structure, wire diameter, wire material and forming pressure used to create the part can control this characteristic.